Latest News

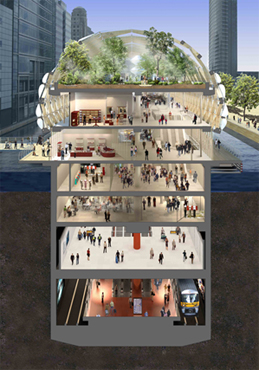

Canary Wharf Crossrail Station

SES applies technologically advanced monitoring systems to meet the stringent demands on this high profile project, which forms part of Britain's most ambitious rail scheme in decades. Under a specification designed by Arup, SES have planned, installed and implemented the project's unique monitoring system.

Crossrail is a 118km long east-west London rail link that is due to be operational in 2017, part of the route involves tunneling 21.5km under central London. A series of stations are planned for the route and the new station at Canary Wharf is now currently under construction. When complete, the station box will be 256m long and up to 30m wide. The site sits in the north dock of West India Quay with the base slab 16m below the dock bed and 25m below water level.

The structural backbone of the station box consists of 295 colossal 18.5m long, 1.2m diameter steel tubular Giken piles, which form the cofferdam. The primary structural support for the coffer dam wall consist of a series of anchor piles offset in the dock with tie rods connecting the anchor piles to the Giken piled wall. This method of support allows works to commence within the drained coffer dam without the need for internal propping at the upper levels.

Piles

The Giken Piles are monitored using 21 inclinometers, with a further 16 inclinometers being strategically installed in corresponding anchor piles. With this data SES creates deflection plots which accurately indicate the extent of movement at specific intervals along the full depth of the piles.

Tie Rods

21 load cells have been installed at key locations where the tie rods connect to the piled wall. The load cells, via an automated system, measure the force in the tie rods caused by the water pressure at the back of the wall while the dock is drained. This system will also be essential during the excavation of the station box to full depth.

Capping Beams

A real-time monitoring system involving 4 robotic total stations is also operational. The instruments automatically survey 60 glass prisms on the capping beams and anchor pile heads. The use of robotic total stations ensures regular monitoring of the structure on a continuous basis.

Monitoring Reporting

The field data captured by the instrumentation and data logger is sent back to the SES office and turned into a more user-friendly format i.e. reports, graphs and tables. All of the information is provided by a site-specific password protected website that is updated in real-time. The website not only shows the latest readings, but also provides a portal for all historical information and links the site weather station, webcams, construction diaries and other related information that is useful in interpreting the monitoring results.

Contact SES for all your monitoring requirements and we will be pleased to provide you with expert advice and a service that is cost-effective, accurate and most importantly specific to your needs

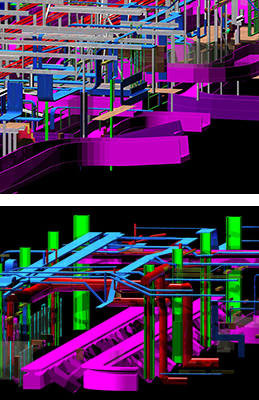

BAA - T4 Baggage handling system

Transferring millions of bags a year, Heathrow Airport's baggage handling system is an intricate network of conveyor belts, and BAA intends to thread additional conveyors through the existing system to help alleviate strain due to the increased demand in capacity. Mace Group called in SES to devise a solution on how to survey the complex chain of conveyors in a manner that is safe and does not interrupt with the day to day operations at the airport. To achieve this SES implemented a laser scanning approach which surveys from known co-ordinated points at a safe distance. Using this method of surveying enables SES to put in to practice safe system of work procedures by keeping our surveyors at a distance from moving machinery. The additional benefits to laser scanning include the ability of our CAD department to produce 3D models of the exact environment, mapping locations of steelwork, pipes, ducts, cables trays, lighting and many more features. With the 3D CAD model the designers and installation team can highlight any potential clashes, identify fixing points and address access issues.

With survey teams working both air and land side, SES continues to strive to deliver a service that is second to none for the aviation industry.

Health & Safety

Site Engineering Surveys Ltd is committed to the highest standards of safety, health and environmental practice.

We provide employees with suitable and adequate systems of work, procedures and guidance to support and assist them in conducting their activities in a safe manner supplemented by regular training.

Current status:

- 100% employee's hold valid CSCS cards

- 100% employee's completed CITB site safety awareness training scheme

- 100% supervisors completed CITB site supervisor's safety training scheme

- 100% managers completed CITB site managers safety training scheme

SES is CHAS approved and have been audited by our leading clients receiving approved accreditation for our Health & Safety. Our policy is under continued review as we look to maintain and promote a positive health and safety culture.

Engineering Surveying - Skyscraper The Shard

The structure which is now visible above ground will be the tallest building in Western Europe at 306m and will rise above London Bridge Station. The Shard with its mix of offices, residences, hotel, restaurants and viewing platforms will herald a new era in high rise development for London and will become emblematic when all eyes look towards the cityin 2012.

SES have been awarded the contract for providing the survey control for the project. With a structure of this height with the anticipated building movements and settlement SES have been required to design a system for transferring the gridline control and level datum's to each level of construction that will ensure a dependable platform is established to allow the trade contractors to set out their works with confidence.

Construction Surveying in the Middle East - Qatar

SES surveys Qatar University for Avanti Systems. The project entailed installing a bespoke pre fabricated internal partitioning system with Tadmur Contracting which required an accurate dimensional survey and setting out to match. In little over a week SES mobilized and was on site setting out gridlines, datum's and capturing important as-built information to enable their designers to produce fabrication drawings.

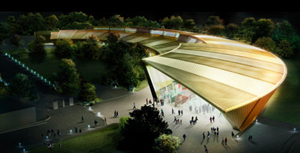

Laser Scanning - Visual Arts Centre

The Visual Arts facility is intended to be a centre of excellence and innovation for culture and learning. The town's new public building will include spaces for art, education, community spaces and leisure activities.

Mace were appointed project manager mid flight through the construction of the project, designed by architect Rafael Vinoly, and required a full as built survey of the structure, to undertake a survey of a building with such a complex geometry SES applied 3D laser scanning technology.

We decided to use 3D laser scanning for approximately 70% of the survey due to the various radial grid systems. Capturing a staggering 280million points the scan enabled us to

- Provide a 3D AutoCAD model

- Generate sections through complicated structural profiles with ease

- Create floor and reflected ceiling plans

- Survey high risk area's such as the roof without the need for high level access

- Minimise time spent in the field

- Eliminate the need for site re-visits

We found that the laser scanner has proved to be superior in this application. Please click on the link to view a 'fly through' of the building. https://www.sesltd.uk.com/laser-scanning.html

SES acquire new Leica TS30 survey instruments

SES is committed to being at the forefront of technology and to use the most advanced equipment which is on offer to the modern day surveyor. We strongly believe that technology can help streamline the process of capturing survey information and it's for this reason that SES has recently required no less than 3no. Leica TS30 total stations, the world's most precise, reliable, and quickest total station.

The TS30 boasts:

- High accuracy angular measurement - 0.5

- SmartEye vision - measures targets up to 3000 m with millimetre accuracy

- Unique high precision PinPoint EDM - precision of 0.6 mm + 1ppm to prisms and 2 mm + 2 ppm to natural surfaces

- Move, Lock, Measure, Transmit - unmatched speed to monitor points. Measurement data is then immediately available for on-board storage, or to be transmitted to any location via cable, radio, mobile phone or the internet.

SES has made this investment to ensure that we deliver to our clients the most accurate and efficient survey service which is second to none.

The Pinnacle

Consisting of 60 floors, 80,420 sq m of floor space and reaching 288 metres, the construction of the Pinnacle in the City of London is now well underway with the demoliltion of the existing basement slabs taking place. The piles have already been bored from the ground floor by installing pile casings from the ground floor slab through the original basement voids.

SES have been appointed by Brookfield to establish a monitoring regime to identify any movements of the existing retaining walls and surrounding buildings. The depth of the new basement and the uncertainty of the construction of the existing retaining walls and with Victorian sewers and modern communication tunnels adjacent to the site perimeter it is essential that the smallest movements be reported.

SES have positioned in excess of 60 tiltmeters in arrays around the existing retaining walls to monitor the walls for movement, by adopting tiltmeters SES are able to monitor the walls continuously, even whilst demolition is taking place directly above, giving real time results that are available to view by the structural engineers and other interested parties via a dedicated website.

Media City UK - Manchester, SES secure cladding package

The Media City project at Salford Quays in Greater Manchester is well on the way and with building B4 out of the ground is set for completion at the end of 2010/2011.

SES has won the Surveying & Setting Out package for the cladding system, the 13 storey building is a combination of stick work and unitised elements. The building has a 2 part splayed grid system from levels 00 to 05 which then steps in to form a rectangular structure between floors 05 to 13. Cladding/Curtain Walling systems today require a high degree of accuracy, by adopting stringent surveying procedures and thorough checking SES can ensure the desired setting out accuracy is achieved. In addition to setting out, SES will provide full as-built drawings of the structure for our client which will keep our client informed of the dimensional accuracy of their work.

We look forward to working on this Bovis Lend Lease site and contributing to a successful project.

National Maritime Museum - Greenwich, London

Construction of the new extension project at the National Maritime Museum, the new Sammy Ofer Wing has recently commenced.

The Bovis Lend Lease project will include custom designed exhibition spaces, learning, research and archive facilities. The architectural concept is to create a scheme that subtly integrates the wing into its surroundings. Funded by an extraordinary £20 million gift from shipping magnate Mr Sammy Ofer KBE, the major new wing is scheduled to open in 2012.

SES have been employed to carry out initial site verification surveys and establish the primary survey control, setting out gridlines and datums to each level of construction and as construction proceeds as built surveys of structural elements will follow .

Serpentine Gallery

Serpentine Gallery is one of London's best-loved galleries for modern and contemporary art. It's Exhibition, Architecture, Education and Public Programmes attracts up to 800,000 visitors in any one year. The Serpentine arts commission builds a new pavilion each year in Kensington Gardens and as a proud sponsor for the past 5 years SES looks forward to participating in the 2010 event.

Measuring up to the challenge

SES seized a great opportunity to give back to the community by having some fun at the Anthony Nolan Charity Dragon Boat Challenge. All funds raised went to help victims of leukaemia and thanks to the fundraising of the team we managed to raise over £1600.

Not only did our team exceed their fundraising target , they also achieved a creditable 2nd place overall on the day. We raise our paddles and say a big thank you to all those who participated and donated to make this a successful Charity event.

Ravenscraig Sports Facility

The area of Ravenscraig in Scotland's Central Belt will become home to over 10,000 people. and is expected to create 12,000 jobs and attract in excess of £1.2 billion of private sector investment over the next 15 to 20 years.

SES is involved with the setting out of the approx 2500 ton steel Sports Facility. The building boasts an indoor football pitch, sports hall, dance studios and much more. We currently line and level the steelwork fabricated by Bonesteel and produce as-built surveys for the hand-over to Balfour Beatty. With the trusses spanning 70m and at a depth of 5m they are indeed considerable lifts. SES intends to complete the setting out of the steel structure within the month.

16 years at Heathrow

SES have recently achieved a staggering 16 years of providing continuous surveying support for the ongoing redevelopment of Heathrow Airport. Commencing in 1993 with a survey of the entire Terminal 1 building to providing survey control and as built surveys for the new Terminal 5 to recent works around the Central Terminal Area, SES project surveyors Jon Fox and Ted Yates have witnessed the transformation of Heathrow, overcoming all the security and operational difficulties experienced from working around the world's busiest airport.

We have carried out building surveys of live baggage handling areas, to setting out stand areas for aircraft to monitoring the erection of the new Terminal 5 roof trusses to setting out piles with GPS to surveying handrails for new staircases - truly a one stop shop for all surveying requirements.